Introduction

The close collaboration between PlantmatiQ, an Original Equipment Manufacturer (OEM) and Agromanager has resulted in a powerful pooling of knowledge of the industrial world and precision agriculture

The OEM was looking for a sparring partner who could think along in the development of their future machines. The result is that since 2018, we have been designing and maintaining the hardware and software for the OEM.

Together with Agromanager, we have reliably translated the “Agromanager” software into hardware and physical actions: “the spraying of trees”. In addition, we were able to provide the necessary tools for Agromanager to benchmark their software solutions on various industrial PCs (IPc’s).

The division of tasks within the collaboration is as follows:

- PlantmatiQ provides plc software and hardware design, and is closely involved in the development of Agromanager’s spray controller application;

- the OEM supplies the spraying systems;

- Agromanager provides the interface between administration, data, GPS system and the PLC.

Problem

For fruit farmers spraying is an essential part of growing fruit. It is of vital importance that every tree or crop receives just enough of spraying fluid. It is not easy to determine the right dose.

The goal has always been: drift reduction. Higher drift reduction means that more accurate spraying can be performed, which reduces the environmental impact and reduces consumption of spray fluids.

Besides adding functionality, work had to be done on the user-friendly operation in order to be able to set the spraying systems more accurately. In addition, the controls had to be prepared for application on a future generation of spraying systems.

Solution

We started out by asking questions: Who are the people using these systems? What are the challenges in doing their work? How can we contribute to a better work environment? In the end, this should be a tool that is easy to use and to maintain.

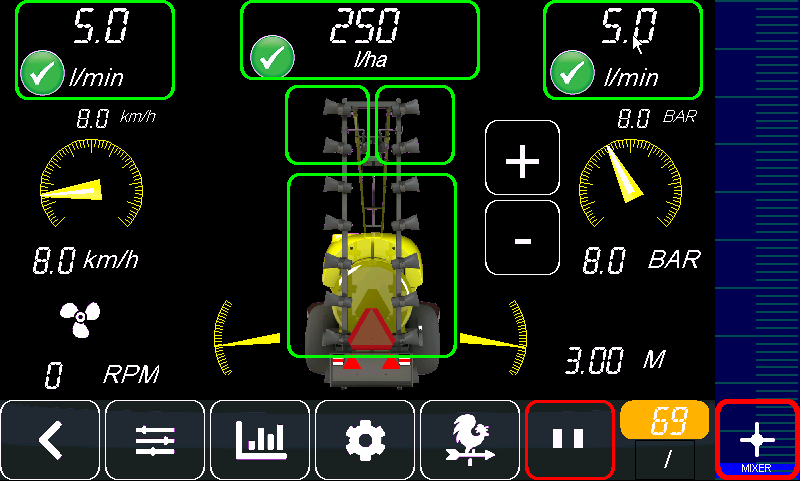

This led, among other things, to an ergonomic design of the main driving screen. Check marks indicate when an optimal spray mist is present, and whether spray caps may be clogged.

The modular design of the hardware and software makes it possible to control every available option with the PLC software. Options can be implemented together or separately, e.g. by making it possible to install a 2020 option on a 2018 spraying system (backward compatibility).

We also thought of the OEM: This system is easy to commission, due to the availability of simple and automated calibration routines.

Always keep thinking along with the customer, and with his customer!

The Next Step

The next step is to test additional functionalities. Some of these are currently being rolled out.

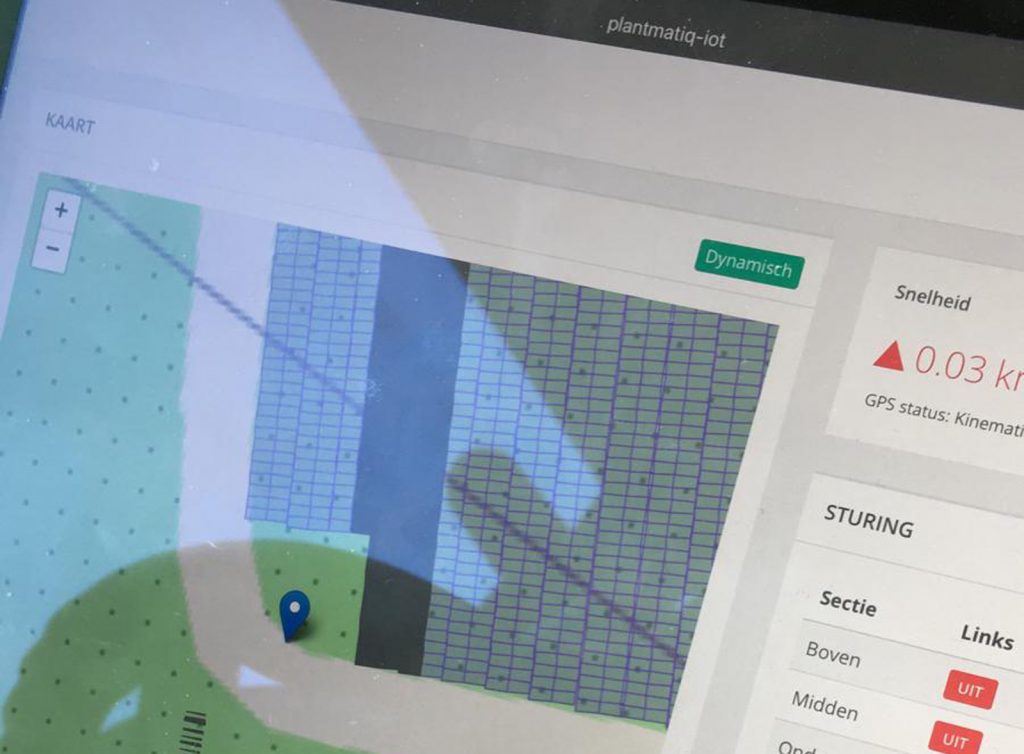

GPS Option

Tests are well on their way to control spraying systems using a “job file” with GPS positions. This makes it possible to choose in advance which trees should or should not be treated (section control). With the GPS module used, an accuracy of 2 cm can be achieved driving at over 8 km/h.

The iPC of this system is equipped with a PlantmatiQ compiled operating system, which is impervious to voltage failure. Remote support is provided by Agromanager or by us over a VPN connection.

I.S.A. (Intelligent Spray Application) Option

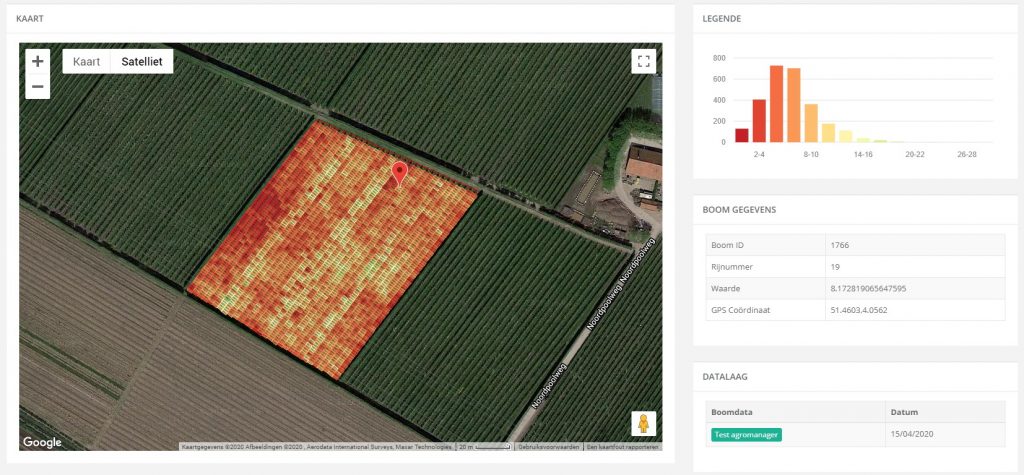

“I.S.A.” is a system that is able to control nozzles based on the leaf mass that is measured. This increases the efficiency of spraying, and on average results in a 25% improvement on the use of water, plant protection products and fertilisers. With this system it will even be possible to control the amount of deposition on tree level.

An additional benefit is that the leaf mass is recorded during measuring. As a result, every time this system is driven through the orchard, a clear picture of the condition of the trees can be obtained. This data can be used for further growth regulation or fertilization.

In Conclusion

Projects like this can only succeed in good cooperation, when knowledge and expertise are shared.

Due to the multifaceted knowledge within IT and OT, we have been able to make a major contribution to an unprecedented piece of innovation within the “hard fruit” sector.

Contact us

Ready to start your next project with us?

That’s great! Feel free to contact us with any question you might have.

Address

Energieweg 30, 3771 NA Barneveld, The Netherlands

Email address

info@plantmatiq.com