"The innovations farmers need are not moonshots"

Timo Hamoen - Co-Founder PlantmatiQ BV

The innovations that the agricultural industry needs are not idealistic moonshots, but practical innovation that builds on existing technology. Equipment manufacturers can take an advantage from other industries that are guiding examples with respect to rapid, targeted innovation.

Take the manufacturing industry as an example. Collecting and analyzing data tools have been very common. Now is time to bring these state of the art technologies in precise engineering, robotics and automation expertise to farming practices. It’s our mission to bring our expertise built over years of working in industrial automation to agriculture to empower modern farming.

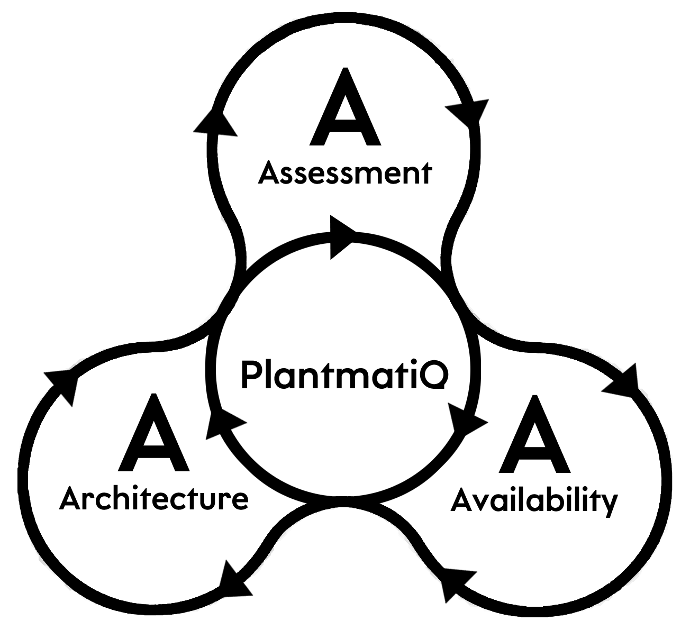

Our approach

You can unlock your products potential with state of the art industrial technology. Plantmatiq shows you exactly how.

To ensure continuous improvement of performance, our modules are constantly updated, future proofing your system – without losing their backward compatibility, obviously.

Assessment

Current portfolio assessed and what pain points are to be addressed with end-user in mind

Architecture

Potential solutions are engineered with latest industrial components plugged into a scalable platform

Availability

24/7 connection to a backoffice for global remote service and support